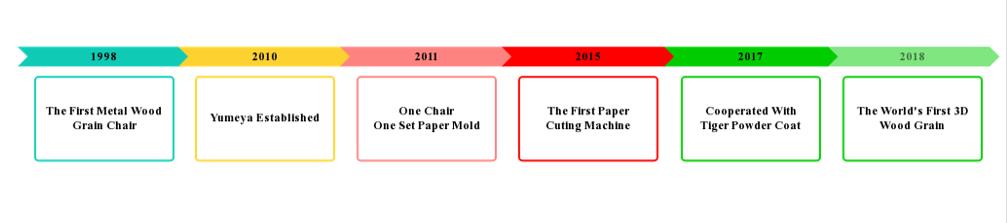

The Development Of Yumeya Metal Wood Grain Chair

From the first Metal Wood Grain Chair to be a pioneer, in these 20 years, Yumeya has never stopped.

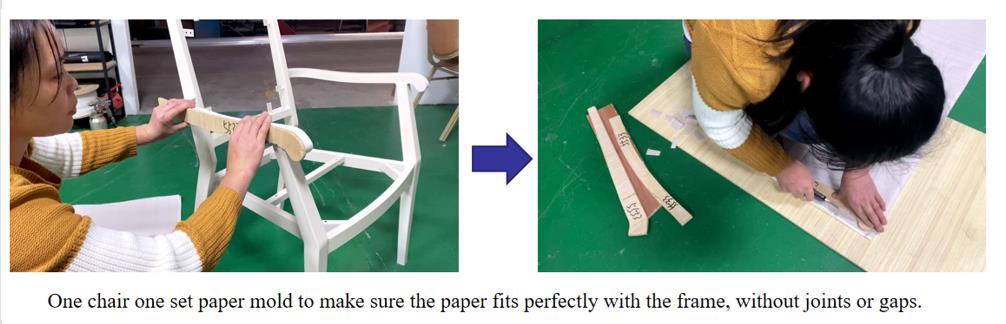

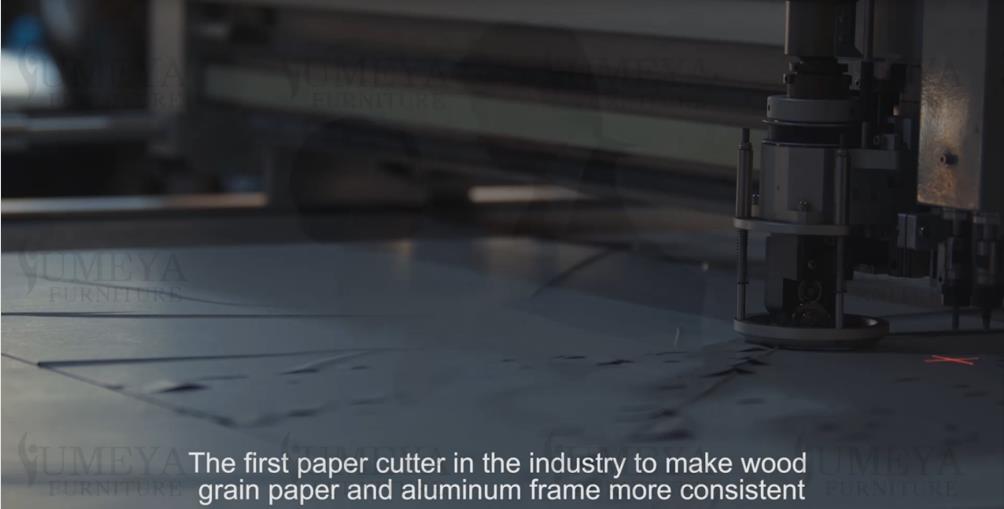

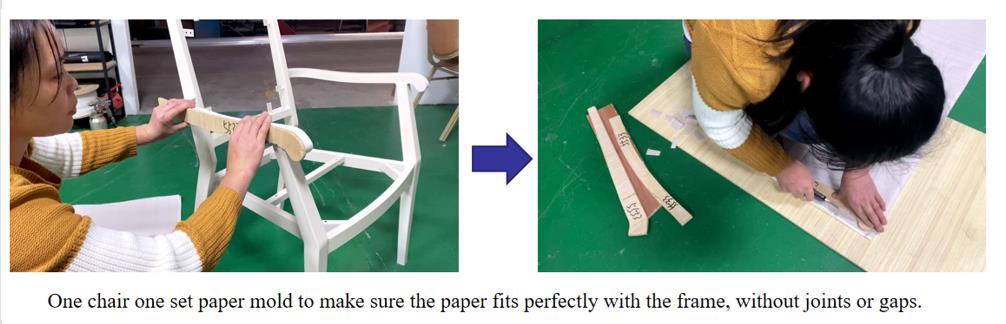

In 1998, Mr. Gong, the founder of Yumeya, developed the first Metal Wood Grain Chair, opened a new era. Since then, wood grain paper overlap problem existed for a long time. At that time, the size of the overlapping area was uneven, even some of the bottom powder was not covered with wood grain texture. In order to solve the problem, after a lot of attempts, in 2011, Yumeya put forward the concept of one chair one set paper mold, which ensured the wood grain paper was effectively consistent with the metal frame. In 2015, in order to solve the problem of efficiency, Yumeya cooperated with the equipment factory to develop the first PCM machine. PCM machine can automatically cut the paper through one-to-one comparison between the frame and wood grain paper, which improves the efficiency by more than 5 times and greatly reduces the cost.

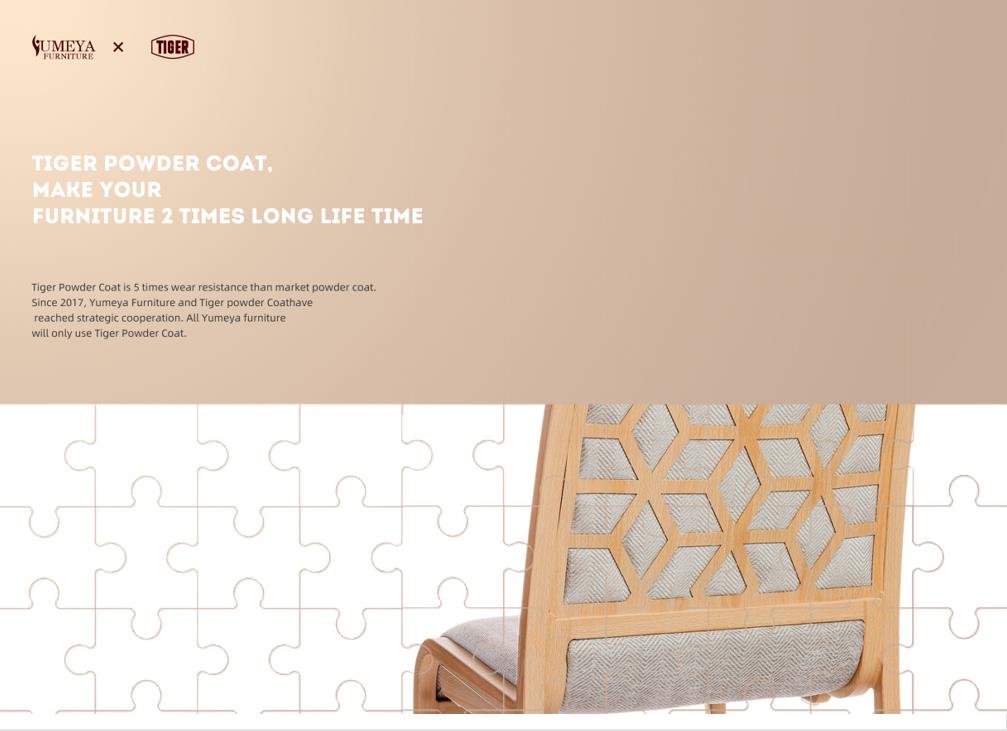

It is impossible for a chair not to collide, especially for the banquet and cafe chairs that needs to be moved frequently. These can lead to scratch & scuffs, causing both a bad first impression and costly furniture replacement. The wear resistance of surface treatment will be particularly important.After testing the powders of different brands at home and abroad, we finally finalized the cooperation with Tiger Powder Coat.

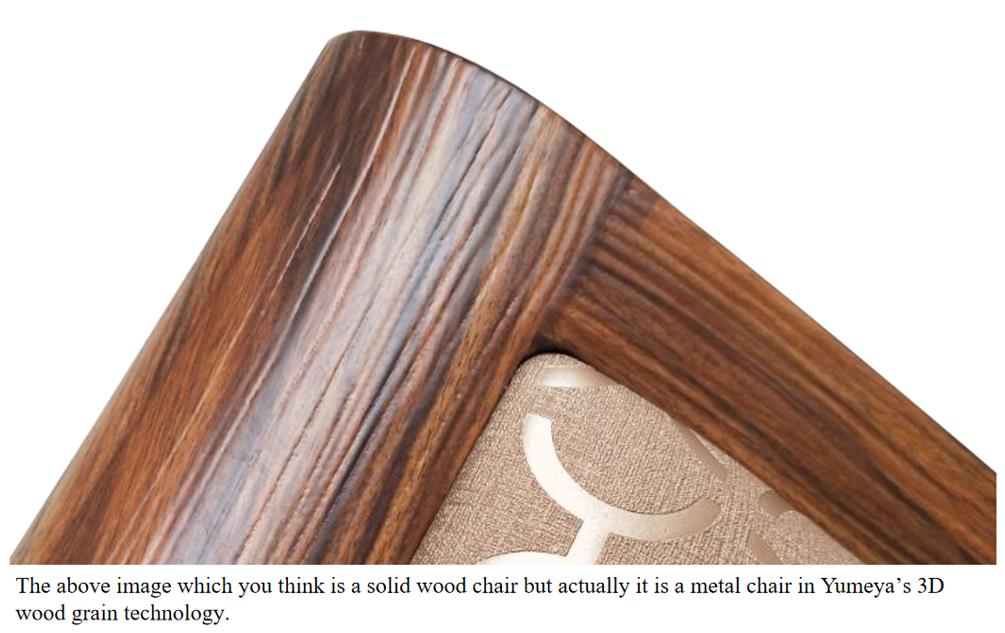

In 2017, Yumeya cooperated with Tiger Powder Coat, an international famous powder coat brand which is professionally produced metal powder. The wear resistance of Tiger Powder Coat is 3-5 times that of Chinese powder coat brands. Meanwhile, the price is lower than the other brands with the same wear resistance. Besides, Tiger Powder Coat is a green product, there are no lead, cadmium and other toxic substances. All these make the products more competitive. Now Yumeya’s Metal Wood Grain Chair can easily deal with daily collisions. You will be surprised to find that Yumeya’s Metal Wood Grain Chair can maintain the good look for years. Since then, Yumeya’s Metal Wood Grain is more realistic. Even if you look close, it looks like solid wood.

In order to better solve the surface treatment problems in daily use, Yumeya & Tiger have jointly launched two technologies pioneered by the industry.

1. Dou™-Powder Coat Technology, Combining the durability of powder coating and the effect of paint

2. Diamond™ Technology, as hard as diamond, no stacking mark will left.

Before 2018, people can only get the wood grain effect on the metal chair visually, but they can't get the wood grain texture tactile. Therefore, after years of research, Yumeya launched the world’s first 3D wood grain technology in 2018. This is a major innovation and breakthrough.3D Wood Grain Technology can maximum restore the solid wood texture. You can see and touch the solid wood texture in the surface of a metal chair. And this innovation makes more and more commercial places favor metal wood grain chairs.

Due to the persistence of COVID-19, the economy is in recession and the outlook is uncertain. People's consumption will also become cautious. When a potential customer who recognizes your company's brand of high quality, but can't afford the high price of solid wood chair, Metal Wood Grain chairs with realistic solid wood texture and higher strength but lower price will be a new and an ideal choice. Metal Wood Grain chair is an effective extension of solid wood chair in market & customer group.

So far, people can get the wood look and touch in a metal chair. Now Yumeya had became a pioneer in the industry of metal wood grain and led the development of the industry.

How to get Metal Wood Finish in a chair? Metal Wood Grain Chairs with more handmade connotation are as valuable as solid wood chairs

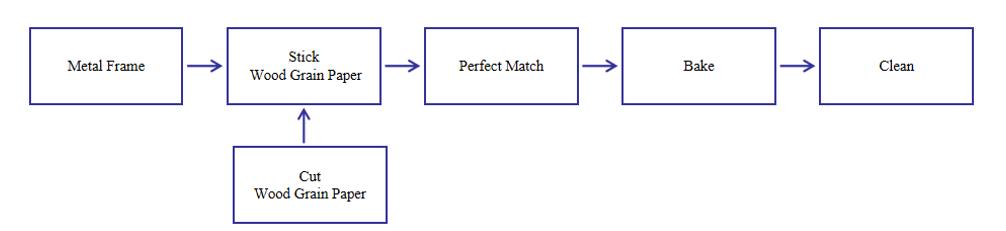

After making the metal frame, it needs 5 processes to complete the production of metal wood grain.

After made the first metal wood grain chair in 1998, Yumeya has been committed to the research of metal wood grain more than 20 years. In a lot of practice, we gradually understand that surface treatment is a system, there are at least 5 key points to obtain perfect metal wood grain effect.

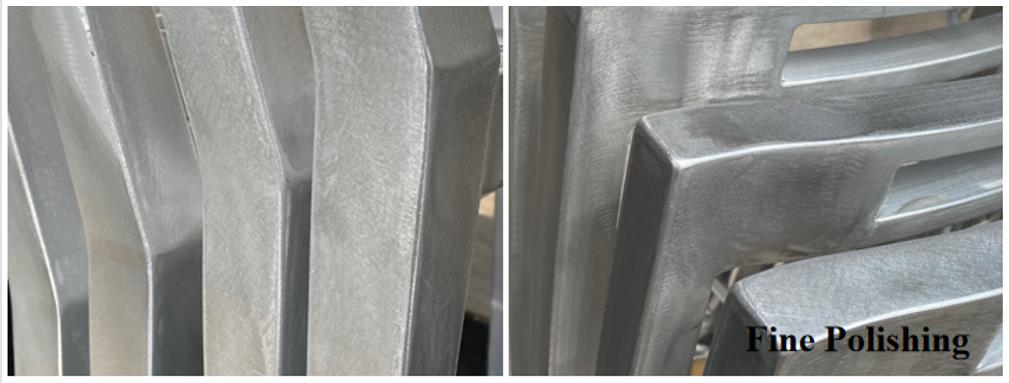

1) Fine polishing

Doing surface treatment in a chair, similar to make-up, first of all must have a smooth frame. All Yumeya chairs need to go through four polishing processes before they can formally enter the surface treatment process. Component polishing --- Polishing after welding --- Fine polish for the whole chair--- Polishing after cleaning. After 4 steps, it can achieve good flat and smooth effect.

2)Good powder coat can effectively develop color

Since 2017, Yumeya cooperate with Tiger Powder Coat for metal powder coat.It can fully display the wood grain texture, increase the fidelity, and provide 5 times of wear resistance.

3)Fine cut, perfect fit

Yumeya is the only factory realized one chair one mold. All the wood grain paper is cut out by the mold that matches the chair.

Therefore, all the wood grain paper can be effectively matched with the chair without any joint or gap.

4)Full contact, ensure the effect of heat transfer

Metal wood grain is heat transfer technology. Therefore, full contact is a key factor. We use high temperature toughness plastic mold to ensure the wood grain paper and the powder full contact to achieve a clear effect.

5)Precise temperature and time control

Time and temperature are a subtle combination. Any change in parameters will affect the overall effect, or not wear-resistant, or color different. After years of exploration, Yumeya has found the best combination of time and temperature to ensure the best wood grain effect.

Metal wood grain chair is not a traditional metal chair. It is more valuable because there are a lot of manual production. Metal Wood Grain is an effective extension of solid wood chair in market & customer group.If you want to learn more about Yumeya Metal Wood Grain, please feel free to contact me. Thanks.

Email: info@youmeiya.net

Phone: +86 15219693331

Address: Zhennan Industry, Heshan City, Guangdong Province, China.

Products